BC Wildfire Service / WorkSafeBC

S100A Annual Fire Safety Refresher Training - Part 4

11. Water Delivery Systems

We will briefly review the water delivery systems section that was covered in detail in your two-day, 16-hour S100 course that included both a classroom day and a field day. The S100 Basic Fire Suppression and Safety course's Student Workbook [3] expands and details water delivery system principals, trouble-shooting and maintenance procedures. [ 16 ] ![]() If you no longer have your copy, we recommend that you obtain a copy of the workbook, which is available for purchase at the end of this course, and keep it available for reference during the fire season.

If you no longer have your copy, we recommend that you obtain a copy of the workbook, which is available for purchase at the end of this course, and keep it available for reference during the fire season.

The Pump Site

The ideal pump site is on level, solid ground, close to and at the same level as the water source, and free from fireline hazards. Variability in the landscape requires that you adapt and establish a safe, effective site. In addition to avoiding fireline hazards when selecting a pump site, firefighters must:

- Stay away from poorly ventilated sites that allow the buildup of high concentrations of carbon monoxide;

- Situate the pump in a manner that eliminates the chance of dry fuels being ignited by the pump exhaust;

- Always wear hearing protection when pump engines are running.

Managing the Pump Site

A properly managed pump site will be clean, organized and will have ensured the following:

- Pump is secure, supported off of soft or wet ground and staked/roped as necessary;

- Fuel containers are secure, in a berm and in sufficient quantities required for pump operations;

- Bleed-off line is located well away from the pump;

- Tool box is complete, secure with no tools lying around;

- Foam use complies with safety and environmental regulations;

- Risk of theft adjacent to roads has been addressed.

The Pump

Wildland firefighter must be familiar with the features and operations of the pump unit(s) they are using. Make sure you take the time to familiarize yourself with the operations, trouble-shooting and maintenance procedures for the pump(s) used on your worksite. Download a digital copy of the Owner's Manual and print a copy or keep it on your cell phone. Also ensure you are familiar with the pump's technical information including:

- Engine type;

- Total head;

- Suction head;

- Discharge capacity.

Pump Equipment Required

A water pump is just one component of the wildland fire pump system. You must have all of the components of the system on site or it will not function:

- The pump;

- Fuel;

- Suction hose;

- Tool kit;

- Discharge hose(s) and fittings.

All pumps must be fueled with the correct type of gasoline. Operating a two-cycle engine with straight gas or a four-cycle engine with mixed gas will seriously damage costly equipment. If firefighters have any doubt regarding the type of gasoline in a fuel container, they should not use it.

Pump Set-up Procedure

Firefighters must develop the routine of checking all pump system components for serviceability and completeness. Experienced firefighters take no chances and double-check the condition of the pump, other components, as well as the contents of the tool box before they are sent to the field.

The pump set-up procedure is a basic routine that all firefighters must be completely familiar with. The key to success is hands-on practice. Firefighters must practice pump set-up until it can be carried out quickly with no steps being forgotten or overlooked:

- Fuel supply to the engine;

- Hooking up water supply to the pump;

- Starting the engine;

- Once the engine is running;

- Stopping the engine.

Pump Safety

- Prior to starting any small engine equipment put on approved hearing protection;

- Always signal to the nozzle team to ensure they are prepared, prior running the pump at full throttle;

- The muffler on all pump engines will be hot after extended use - never touch the muffler when it is hot;

- If water flow has been shut down and a pump has been left operating at maximum power for 10 minutes or more, shut the engine down immediately and let the pump chamber cool before attempting any repairs;

- If spark plug has been pulled to troubleshoot spark/ignition issues, never stand over the spark plug opening when pulling the starter cord - the gas vapour being vented is harmful, very flammable and may explode if ignited.

Safety Considerations for the Water Delivery Crew

Communication is a key safety consideration for the water delivery crew. Both fire control strategy and crew safety are reliant on a stable supply of water.

Firefighters must use all water wisely to maximize effectiveness from each litre, especially with fires where water is limited. This is a key responsibility of the nozzle person. A Crew Leader may monitor nozzle use and correct poor technique or even replace the nozzle person with a more qualified firefighter.

Firefighters must have back-up fire control capability in case the water delivery system fails or sufficient water is unavailable. The most efficient fire control is a combination of hand tool work and water delivery.

Fire Extinguishing Agents

A substance that, by physical or chemical action, reduces the flammability of combustible materials is known as a fire retardant. They are classified into two types:

- Long-term fire retardants;

- Short-term fire retardants.

Short-term fire retardants include:

- Class A foams ('wildland foams'): used on fires of porous fuels like wood and paper, and also rubber and plastic;

- Class B foams: used primarily by structural firefighters and rescue personnel on flammable liquid fires - most commonly observed by wildland firefighters during interface fires.

Safe Working Practices for Foam Use

Firefighters who work with foam must adhere to the following safe work practices:

- Wear rubber gloves, rubber boots and eye protection when handling foam concentrate;

- Ensure an eyewash kit is available at the mixing site;

- Use a barrier cream;

- Avoid prolonged or repeated skin contact;

- Wash exposed skin as soon as possible;

- Remove and wash clothing contaminated by spills of foam concentrate;

- Do not re-use foam concentrate containers for storing other liquids;

- Do not mix different foam concentrate products together.

12. Helicopter Use and Safety

Helicopter Danger Areas

The three primary danger areas around any helicopter are:

- Main rotor;

- Tail rotor;

- Exhaust.

Main Rotor

The main rotor of most helicopters used to transport firefighters is centered approximately 3 meters (10 feet) above the ground. The rotor tips can, at times, drop to within 1.25 meters (4 feet) of level ground. This creates a hazard to anyone under the main rotor's span. An uphill slope or a slight rise in terrain can also expose an individual to the main rotor. The main rotor will kill you if it strikes you. Other factors that also can lead to a reduction in main rotor height are:

- Wind gusts;

- Landing on an off-level site, near slopes or on uneven ground;

- Pilot manipulating controls to maintain stability or maneuver the helicopter.

Tail Rotor

A tail rotor is extremely dangerous and virtually impossible to see when spinning at a high rate. On most helicopters the tail rotor is situated at a height where it can strike your head or chest and instantly kill you. Never go near the tail rotor. Never walk any further back than the helicopter's baggage compartment.

Exhaust

Some models of helicopters have exhaust ducts that are located close to the ground. Exhaust gases can have temperatures of several hundred degrees. Exhaust gases and metal shrouds can instantly and seriously burn an individual.

Helicopter Safety Briefing

The helicopter safety briefing is a pre-flight meeting with the pilot and the personnel working around the helicopter. The pilot provides all of the safety and operational information relevant to their machine. If you have not flown in a helicopter or it has been a while since your last flight, make sure you request a briefing from the pilot.

You should expect a briefing when:

- A new pilot or helicopter is to start work with the crew;

- A new person (firefighter or ground personnel) is to start work with the helicopter;

- Operating procedures have changed;

- The pilot, crew leader, or an individual requests a helicopter safety briefing.

Approaching the Helicopter

Source: British Columbia S100 Basic Fire Suppression & Safety Student Workbook [ 17 ]

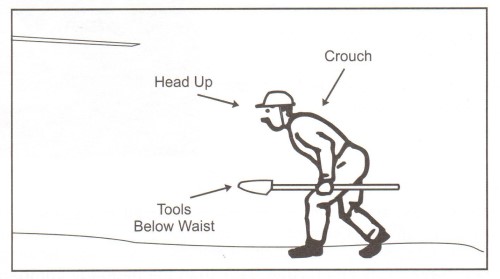

When approaching or departing the helicopter:

- Never approach or depart a helicopter without obtaining the pilot's approval - obtain a signal (usually a nod);

- Always approach from or depart towards the downhill side of a helicopter;

- Always approach and depart from the front of a helicopter (unless it slopes uphill) so you remain visible to the pilot and keep away from the tail rotor;

- Crouch (and look where you are walking) when in the vicinity of helicopters;

- Do not raise anything above your head;

- Always carry tools low to the ground (never upright or resting on your shoulder);

- Never throw anything in the vicinity of a helicopter;

- Walk (do not run) when working around helicopters;

- Keep motor vehicles far away from helicopters;

- Keep dogs and other animals tied up when helicopters are taking-off or landing.

Helicopter Bucketing Safety

Helicopter bucketing operations frequently take place near ground operations and can create potentially hazardous situations. It is crucial to ensure separation between the bucketing operation and ground operations. Firefighters must:

- Be alert during bucketing operations;

- Stay clear of the drop zone (firefighters can be injured if struck by retardant or water).

Hazardous situations that firefighters must be alert for during bucketing operations include:

- Accidental release of the entire bucket assembly, which can cause serious injury if it hits an individual on the ground;

- Out-of-control buckets as well as rotor wash can bring down unstable trees and/or widow-makers onto firefighters below;

- Rotor wash can increase fire activity following bucketing drops and lead to fire entrapment events.

Helicopter Long-line Safety

Long-lining is a system of hanging loads on a line below the helicopter and is frequently used to pick-up, transport and deliver equipment and supplies to firefighting crews:

- Only trained individuals can be engaged in hooking and hooking loads;

- Always maintain a safe distance from long-line operations;

- Stay alert as these loads can be accidently released at any time;

- Uncontrolled loads as well as rotor wash can bring down unstable trees and/or widow-makers onto firefighters below.

13. Fireline Aircraft (Fixed Wing)and Safety

Airtankers in British Columbia

Fixed-wing airtankers are very effective in firefighting and are utilized extensively by the BC Wildfire Service. Firefighters can be injured or killed if they get caught in a drop zone while a retardant drop is underway. The retardant is also very slippery and can result in injuries if extreme caution is not used when travelling through a drop zone.

Drop Notification

If the incident commander and the aircraft are radio contact, ground crews will be told when the tanker(s) is/are approaching for a retardant drop. Additional measures are also taken to notify firefighters of impending drops.

Normally (but not always), a smaller lead aircraft (bird-dog) arrives at the drop zone in advance of the air tanker(s). The bird-dog will make a pass following the flight path of the airtanker drop and use its PA system to warn firefighters of an impending drop as well as completion of the drop using the following procedures:

Drop Warning - Warbler (Yelping Sound)

Source: Conair Aerial Firefighting, Abbotsford, British Columbia, Canada V2T 6H5 [18]

A warbling (yelping) sound warns of an impending retardant drop. Firefighters must clear the area and take cover as soon as possible.

To move safely out of the drop zone:

- Walk, don't run, at right angles to the drop path to a location at least 30 m (100 feet) away from the target;

- Stay clear of large coarse woody debris, rocks and other materials that could be knocked loose by the drop, especially if you are downhill;

- Stay clear of overhead hazards such as danger trees, snags, powerlines and power poles.

If you are caught by surprise in a drop zone, follow these emergency procedures:

- Place hand tools to the side, behind or downhill from your body;

- Lie on the ground, face down, hard hat on, facing approaching plane;

- Grab on to something firm to anchor yourself;

- If you get covered by retardant, keep it out of your eyes.

All Clear - Siren

Source: Conair Aerial Firefighting, Abbotsford, British Columbia, Canada V2T 6H5 [19]

A siren indicates "all clear" and firefighters can return to normal work activities.

Single Airtanker (No Bird-Dog)

If an airtanker is alone, they will make a single pass in advance, following the flight path of the drop, before dropping their retardant.

14. Wildland / Urban Interface Safety

Wildland / Urban Interface Fireline Hazards

In addition to wildland fire hazards firefighters encounter, this environment contains hazards such as:

- Inadequate vehicle access and escape routes;

- Overhead electrical powerlines;

- Propane tanks and natural gas lines;

- Hydrogen Sulfide gas if oil and gas installations are present;

- Unknown fuel types (buildings, vehicles, etc.);

- Hazardous materials including pesticides, explosives, solvents, garden / farm chemicals and ammunition.

15. WHMIS / TDG Awareness

Workplace Hazardous Material Information System (WHMIS - 2015)

WHMIS legislation requires that every individual who works with, or in proximity to, hazardous materials is annually trained in WHMIS - 2015. This training is covered in a separate course.

Transportation of Dangerous Goods (TDG)

Transportation of Dangerous Goods Regulations requires that any individual who handles, offers for transport or transports dangerous goods must be trained and certified. This training is covered in a separate course.